As a seasoned technician in industrial communication, I’ve witnessed the lightning-fast evolution of connectivity technologies. Today, I’m thrilled to share my insights on a game-changing product that’s been turning heads in our industry – the SeDTU300 series 4G/CAT4 industrial-grade DTU. This device isn’t just another cog in the machine; it’s the backbone of tomorrow’s smart factories.

First Encounter with SeDTU300: A New Chapter in Industrial Connectivity

When I first laid eyes on the SeDTU300, I’ll admit, it didn’t look like much. But as they say, don’t judge a book by its cover. This little powerhouse packs a punch that left me slack-jawed. Leveraging LTE 4G/CAT4 wireless networks, it serves up a TCP/IP-based wireless data transmission channel that’s a godsend for industrial users. In layman’s terms, it’s like having a universal translator between your industrial equipment and control center, making remote control a walk in the park.

Core Strengths: Rock-Solid Performance

As a tech guy, stability and reliability are my bread and butter. The SeDTU300 knocks it out of the park in this department:

- High-performance MCU chip: It’s rocking an industrial-grade MCU with an embedded real-time operating system. Translation? This baby runs smoother than a well-oiled machine.

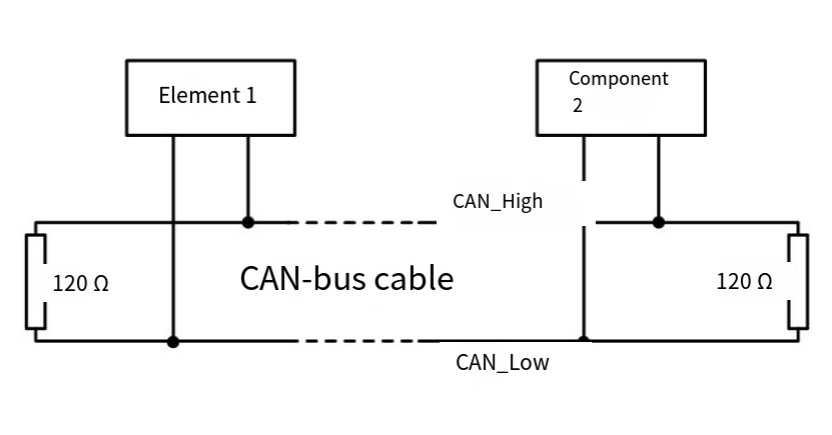

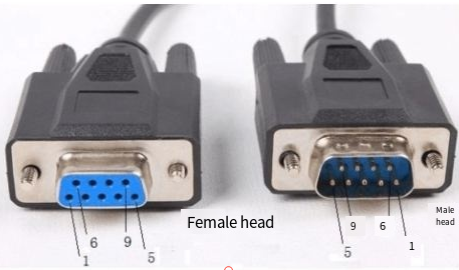

- Interface bonanza: With RS232, RS485, and a smorgasbord of IO interfaces, it’s ready to shake hands with just about any serial device out there. Data transmission and IO collection? It’s got you covered.

- Dual data center backup: Not only does it support dual data center backup transmission, but it can also sync with up to five data centers. Talk about having your bases covered!

Configuration: Flexibility is the Name of the Game

In the field, I’ve found the SeDTU300’s configuration options to be a real lifesaver:

- Local PC configuration tool? Check.

- AT command configuration? You bet.

- TCP/IP remote configuration? Absolutely.

- SMS parameter configuration? Why not!

This Swiss Army knife of configuration options is a field engineer’s dream, streamlining on-site work and slashing system operation costs.

Protocol Conversion: Bridging the Gap

In the industrial world, protocol incompatibility can be a real headache. The SeDTU300 is like industrial-strength aspirin. It supports ModbusTCP/Modbus RTU protocol conversion, seamlessly bridging industrial SCADA systems and field equipment. It’s like having a universal adapter for your industrial communication needs.

Remote Management: Maintenance Made Easy

As someone who’s logged more miles than I care to count for on-site maintenance, the SeDTU300’s remote management capabilities are a game-changer. With cloud platform support for remote management, upgrades, and configuration, I can now do most of my work from the comfort of my office chair. My frequent flyer miles might take a hit, but my productivity is through the roof.

Special Applications: Environmental Monitoring’s New Best Friend

Here’s a cool tidbit: the SeDTU300 supports the HJ 212-2017 standard for online monitoring of pollutants. This opens up a whole new world of applications in environmental monitoring. It’s not just about industrial efficiency; it’s about building a cleaner, greener future.

IO and AI Interfaces: Expanding Horizons

With 2 IO routes and 2 AI routes, the SeDTU300 isn’t just a one-trick pony. It can handle digital input/output and analog current/voltage input collection. This versatility transforms it from a simple communication device into a multi-functional data acquisition terminal.

Conclusion: The Rising Star of Industrial Communication

As a technician, I’ve had the privilege of experiencing firsthand the convenience brought by the SeDTU300. It’s more than just a communication device; it’s a catalyst for the industrial Internet of Things era. From its rock-solid performance and flexible configuration options to its powerful protocol conversion capabilities, the SeDTU300 is undoubtedly a frontrunner in today’s industrial communication landscape.Looking ahead, I believe devices like the SeDTU300 will play an increasingly crucial role in industrial development. They’ll be the key links connecting industrial equipment with intelligent control systems, driving the processes of industrial automation and intelligence. As a technician, I’m proud to be part of this industrial revolution and excited to witness more innovative products like the SeDTU300, as we collectively build a smarter, more efficient industrial future.

KEY-IOT

KEY-IOT