The growing demands of modern industrial environments are pushing the boundaries of network communication. As we strive for faster data transfer rates and longer transmission distances, traditional electrical signal communication is showing its limitations. This is where optical signal communication comes into play, offering a robust solution to meet these evolving needs.

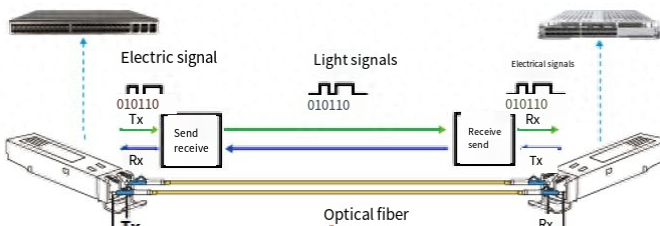

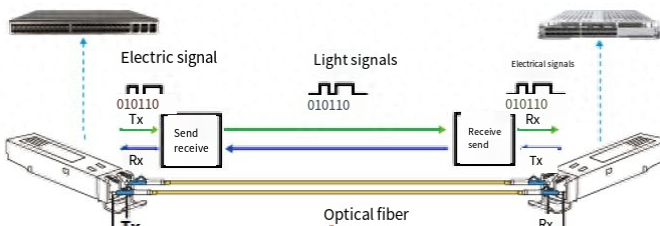

Optical signals have some significant advantages over their electrical counterparts. They experience less transmission loss and are more resistant to interference, making them ideal for long-distance communication. In an optical communication system, data is converted from electrical to optical signals at the sending end, transmitted through fiber optic cables, and then converted back to electrical signals at the receiving end.

Optical signals have some significant advantages over their electrical counterparts. They experience less transmission loss and are more resistant to interference, making them ideal for long-distance communication. In an optical communication system, data is converted from electrical to optical signals at the sending end, transmitted through fiber optic cables, and then converted back to electrical signals at the receiving end.

These systems typically operate in full-duplex mode, allowing simultaneous sending and receiving of data. The key component enabling this electrical-to-optical conversion is the optical module, also known as an optical transceiver.

Let’s dive deeper into the world of optical modules and explore their role in industrial communication:

1. What is an Optical Module?

1. What is an Optical Module?

An optical module, sometimes called an optical transceiver or fiber optic transceiver, is a crucial device in high-speed network communication. It serves as a bridge between electrical and optical systems, with one end connecting to electrical equipment like switches and the other to fiber optic cables. Its primary function is to convert electrical signals to optical for transmission and vice versa for reception.

Optical modules come in two main types: hot-swappable and embedded. Hot-swappable modules can be easily inserted or removed from network devices without affecting other equipment, similar to a USB drive. Embedded modules, on the other hand, are fixed components within network devices.

2. Types of Optical Modules

Optical modules come in various form factors, each designed for specific applications:

– GBIC (Gigabit Interface Converter): Introduced in 2000 for Gigabit Ethernet.

– SFP (Small Form-factor Pluggable): A compact version of GBIC, often called “mini-GBIC,” introduced in 2001.

– XENPAK, XPAK, and X2: Introduced in 2001 for 10 Gigabit Ethernet.

– XFP: Launched in 2005 for 10 Gigabit Ethernet.

– SFP+: An upgraded version of SFP, introduced in 2013 for 10 Gigabit Ethernet.

– CFP (C Form Factor Pluggable): Supports 40Gbps and 100Gbps Ethernet, introduced in 2013.

– QSFP+/QSFP28 (Quad Small Form factor Pluggable): Also supports 40Gbps and 100Gbps Ethernet, introduced in 2013.

3. Siemens Optical Module Products

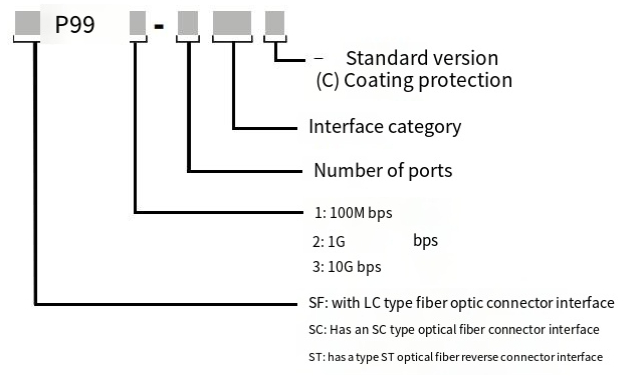

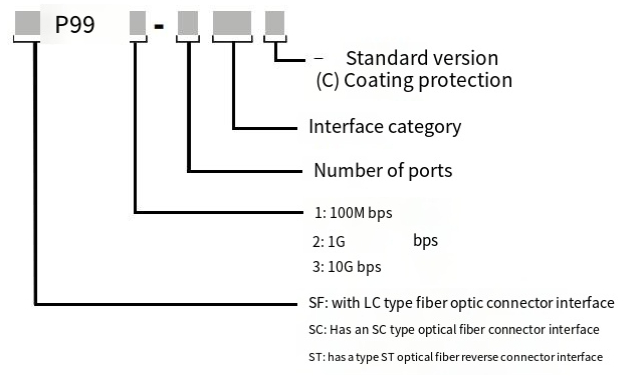

Siemens offers a range of pluggable optical modules, including SFP, SFP+, SCP, and STP types. These fall under the SFP/SFP+ category mentioned earlier.

For example, let’s look at the SFP992-1LD model:

– It uses an LC type fiber optic interface

– Transmission rate: 1 Gbps (Gigabit Ethernet)

– Features one network port

– Uses single-mode fiber with a maximum length of 10km

When selecting optical modules, it’s important to consider factors such as transmission speed, distance, and compatibility with your existing network infrastructure. As industrial communication continues to evolve, optical modules will play an increasingly vital role in ensuring fast, reliable, and long-distance data transmission.

KEY-IOT

KEY-IOT Optical signals have some significant advantages over their electrical counterparts. They experience less transmission loss and are more resistant to interference, making them ideal for long-distance communication. In an optical communication system, data is converted from electrical to optical signals at the sending end, transmitted through fiber optic cables, and then converted back to electrical signals at the receiving end.

Optical signals have some significant advantages over their electrical counterparts. They experience less transmission loss and are more resistant to interference, making them ideal for long-distance communication. In an optical communication system, data is converted from electrical to optical signals at the sending end, transmitted through fiber optic cables, and then converted back to electrical signals at the receiving end. 1. What is an Optical Module?

1. What is an Optical Module?