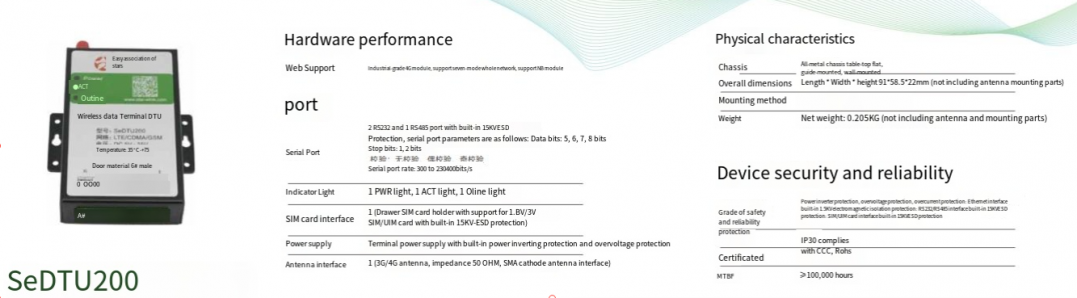

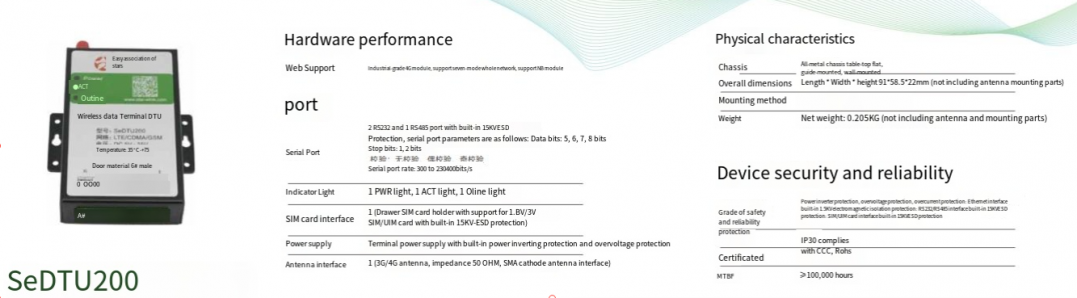

In the heart of Vietnam’s bustling Binh Duong province, a large textile manufacturing plant faced significant challenges in modernizing its operations. The factory, spanning over 50,000 square meters and employing more than 2,000 workers, was struggling to keep up with the increasing demands of global fast fashion brands. The management recognized the need for a robust Industrial IoT solution to improve efficiency, reduce downtime, and maintain quality control. This is where KEY-IOT stepped in with its cutting-edge SeDTU200 4G LTE i ndustrial modem.

The Challenge:

The textile factory was grappling with several issues common to the region:

1. Unreliable power supply: Frequent power outages disrupted production and data collection.

2. Harsh environmental conditions: High humidity and temperatures affected equipment performance.

3. Limited IT infrastructure: The factory lacked a comprehensive wired network.

4. Diverse machinery: A mix of modern and legacy equipment complicated data integration.

5. Language barriers: Many workers were not fluent in English, making system adoption challenging.

6. Cost concerns: The factory needed an affordable solution that could scale.

KEY-IOT’s Approach:

After a thorough on-site assessment, KEY-IOT proposed a comprehensive Industrial IoT solution centered around the SeDTU200 4G LTE industrial modem. The deployment process was carefully planned to address the unique challenges of the Southeast Asian environment:

1. Network Infrastructure:

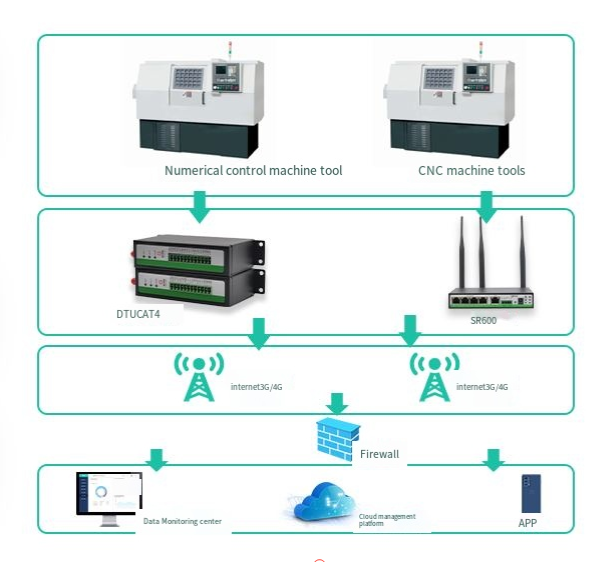

Given the factory’s limited IT infrastructure, KEY-IOT leveraged Vietnam’s robust 4G LTE network. The SeDTU200’s support for multiple network standards (CAT4/CAT1/NB) ensured reliable connectivity even in areas with varying signal strength.

2. Equipment Integration:

The factory’s diverse machinery posed a significant challenge. KEY-IOT utilized the SeDTU200’s versatile interface options:

– RS232 ports were used to connect with newer CNC machines and quality control equipment.

– RS485 interfaces linked older production line controllers and power monitoring systems.

The modem’s support for multiple protocols (MQTT, Modbus, etc.) allowed seamless integration of various devices into a unified system.

3. Environmental Considerations:

To combat the region’s high humidity and temperatures, KEY-IOT took advantage of the SeDTU200’s robust design:

– The wide operating temperature range (-35°C to +75°C) ensured reliable performance even in the factory’s non-air-conditioned areas.

– The metal casing with IP30 protection safeguarded against dust and moisture.

4. Power Management:

To address the unreliable power supply, KEY-IOT implemented a two-pronged approach:

– The SeDTU200’s wide voltage input range (DC 5~36V) allowed for flexible power options.

– Backup power systems were installed, with the SeDTU200’s low power consumption (<150mA at 12V) ensuring extended operation during outages.

5. Data Security:

Given the sensitive nature of production data, KEY-IOT utilized the SeDTU200’s built-in security features:

– APN/VPDN support for secure network access.

– Encrypted data transmission to protect against industrial espionage.

6. User-Friendly Interface:

To overcome language barriers, KEY-IOT developed a custom, icon-based dashboard in Vietnamese. This intuitive interface allowed workers to easily monitor machine status and production metrics.

Deployment Process:

Deployment Process:

1. Site Survey and Planning (Week 1-2):

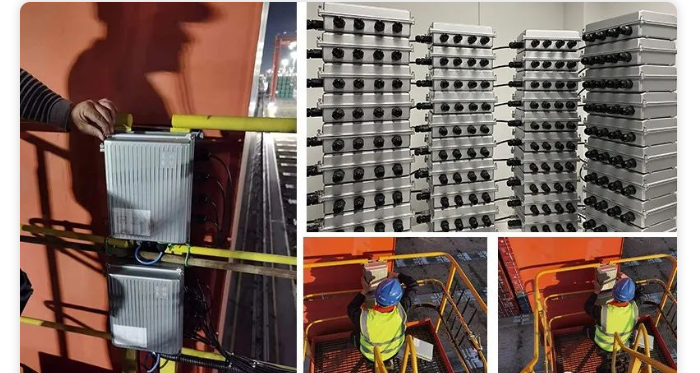

KEY-IOT engineers conducted a comprehensive site survey, mapping out optimal locations for SeDTU200 installations. They worked closely with factory management to identify critical machines and processes for monitoring.

2. Initial Installation and Testing (Week 3-4):

A pilot deployment was initiated in one production line. This phase allowed for fine-tuning of the system and demonstrated its benefits to skeptical stakeholders.

3. Full-Scale Deployment (Week 5-8):

With lessons learned from the pilot, KEY-IOT rapidly expanded the installation across the entire factory. Over 100 SeDTU200 units were strategically placed to cover all critical equipment.

4. Integration and Data Flow Setup (Week 9-10):

KEY-IOT engineers configured the data flow from the SeDTU200 units to the central management system. They set up real-time monitoring dashboards and automated alert systems.

5. Staff Training (Week 11-12):

Comprehensive training sessions were conducted in Vietnamese, ensuring that factory staff at all levels could effectively use and maintain the new system.

6. Optimization and Fine-tuning (Week 13-16):

KEY-IOT engineers remained on-site for a month post-deployment, continuously optimizing the system based on real-world performance and user feedback.

Results and Benefits:

1. Improved Efficiency: Real-time monitoring allowed for quick identification and resolution of bottlenecks, increasing overall production efficiency by 15%.

2. Reduced Downtime: Predictive maintenance alerts, enabled by continuous data collection, reduced unplanned downtime by 30%.

3. Enhanced Quality Control: Automated data collection from quality check points resulted in a 20% reduction in defect rates.

4. Energy Savings: Power consumption monitoring and optimization led to a 10% reduction in energy costs.

5. Improved Worker Safety: Real-time environmental monitoring ensured better working conditions, reducing heat-related incidents by 40%.

6. Data-Driven Decision Making: Access to comprehensive production data allowed management to make more informed decisions on resource allocation and production planning.

Conclusion:

KEY-IOT’s deployment of the SeDTU200-based Industrial IoT solution in this Vietnamese textile factory showcases the transformative power of smart manufacturing technologies in Southeast Asia. By carefully considering the unique challenges of the region and leveraging the versatile capabilities of the SeDTU200 4G LTE industrial modem, KEY-IOT delivered a solution that not only met but exceeded the client’s expectations.

KEY-IOT

KEY-IOT

Deployment Process:

Deployment Process: