4 Reasons Why CANBus Dominates Industrial Communication

The advantages of CANBus communication can be summarized in the following four points:

1. Enhanced field-level information integration capabilities

CANBus can acquire a wealth of information from field devices, better meeting the information integration requirements of factory automation and industrial systems. As a digital communication network, CANBus enables the transmission of device status, fault, and parameter information. In addition to remote control, CANBus communication systems can also perform remote parameterization.

2. Open architecture, interoperability, interchangeability, and integrability

CANBus communication systems are open, allowing engineers to integrate the required control technologies and process workflows into the communication system. Moreover, products from different manufacturers that adhere to the same CANBus communication standards possess interoperability, interchangeability, and ease of integration.

3. High reliability and maintainability of CANBus communication systems

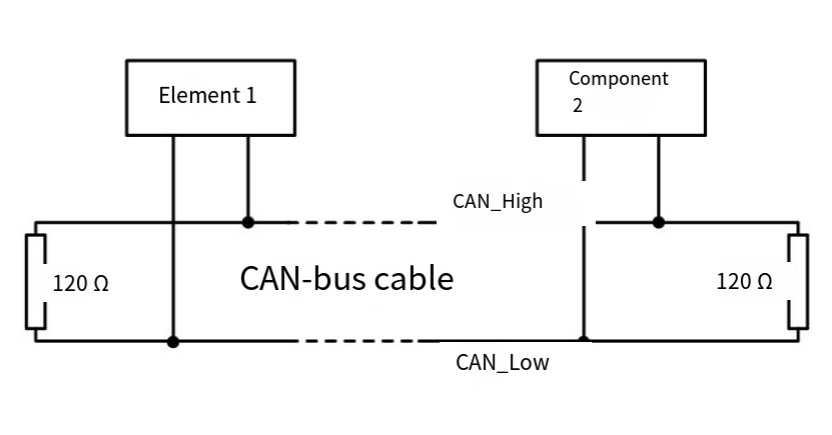

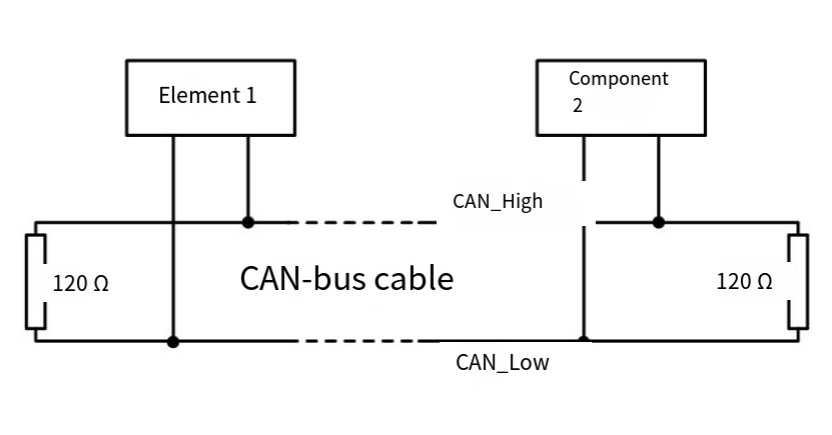

Communication systems based on CAN bus utilize serial connections instead of one-to-one I/O wiring, reducing the wiring between nodes for large-scale I/O systems. Furthermore, CANBus communication systems feature online fault diagnosis, alarm, and recording functions, enabling remote monitoring and data modification of field devices, thus enhancing system maintainability.

4. Reduced engineering wiring costs

For large-scale and widely distributed I/O systems, a significant amount of wiring costs can be eliminated, reducing overall project costs.

KEY-IOT

KEY-IOT