A machine tool manufacturing enterprise needed to achieve wireless connectivity for CNC machine tools within their factory to transmit machine operation data and monitor machine status. However, the factory had severe electromagnetic interference, and the WiFi signal was frequently interrupted, making reliable wireless communication impossible. To solve this problem, our company customized a wireless communication solution based on the SR500 industrial router for the customer.

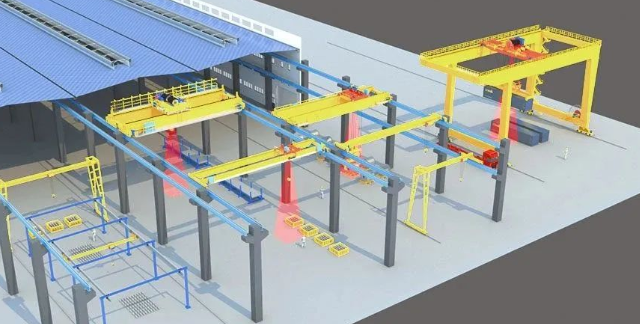

First, our engineering and technical personnel conducted a comprehensive on-site survey of the customer's factory to understand the factory layout, the location of various electromagnetic equipment, and the estimated number of machine tools to be connected. After a detailed assessment of the factory's electromagnetic environment, we decided to set up 4 SR500 routers in the workshop and combine them with the customer's existing Ethernet wiring to build a wireless MESH network, achieving redundant transmission of wireless machine tool data.

During deployment, we installed SR500 routers in the four corners of the workshop and connected them to the existing Ethernet interfaces. The SR500 router has an industrial-grade design with a robust structure that can adapt to harsh environments. We also selected high-gain directional antennas to maximize wireless signal coverage. Through the MESH network function, the 4 routers achieve wireless interconnection and serve as a backup for the wired network, ensuring the reliability of the wireless connection.

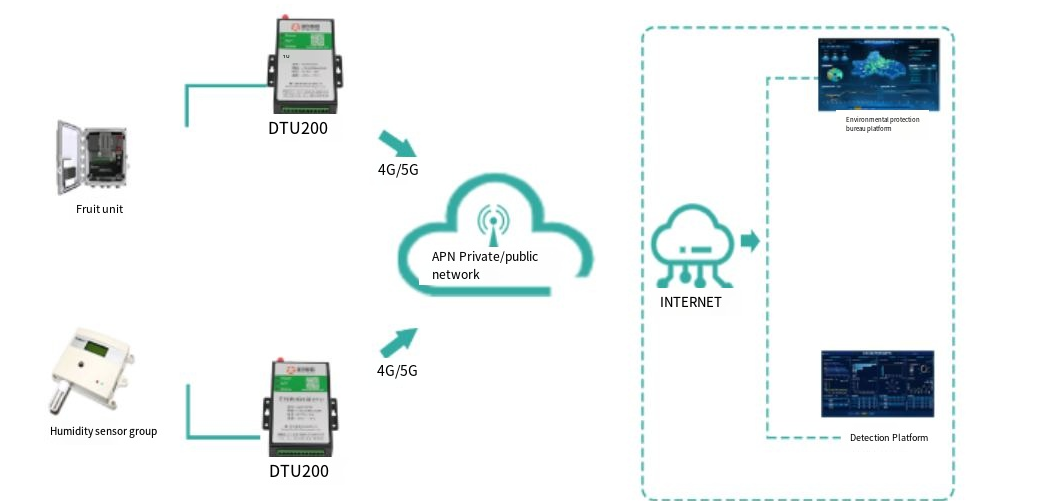

After installation, our engineering and technical personnel debugged the network, selecting wireless parameters suitable for the factory environment, including channels and transmit power, to achieve optimal wireless coverage. At the same time, we configured the VPN function on the routers to ensure the security of machine tool data. We also enabled the router's intelligent DTU function, allowing the customer's CNC machine tool data to be securely and reliably transmitted over the wireless network.

Ultimately, the solution successfully achieved wireless connectivity for all CNC machine tools in the factory and reliably transmitted machine operation data to the monitoring system. On-site testing showed that even in the worst electromagnetic environment, the wireless network availability could still reach 99.95%, fully meeting the customer's requirements. The customer was very satisfied with the wireless communication solution we provided.

Through this project, we fully verified that the SR500 router supports various network access technologies such as 4G, and combined with the intelligent MESH network function, it can effectively address communication challenges in complex industrial environments and achieve reliable wireless data transmission, securely connecting on-site devices with monitoring systems. We firmly believe that the wireless communication solution based on the SR500 router can help more customers achieve industrial wireless connectivity and establish intelligent manufacturing systems.

KEY-IOT

KEY-IOT