The steel industry is a large complex process industry and is in the middle of the entire manufacturing chain, with massive amounts of data, rich scenarios, and extensive connections. In recent years, steel enterprises have actively responded to national policies to limit total steel production, but the demand for labor in plant areas has only increased, as have technological requirements. To adhere to the principle of "increasing production without increasing personnel", many steel enterprises have embarked on the path of "full automation".

Metallurgical plants have many dangerous scenarios and harsh environments, jobs requiring heavy physical labor and repetition, a large number of devices requiring manual inspection, lack of online monitoring technology, placing higher demands on the experience and quality of equipment management personnel, affecting work efficiency and production efficiency. The urgency to improve labor efficiency leads to a pressing need for smart manufacturing.

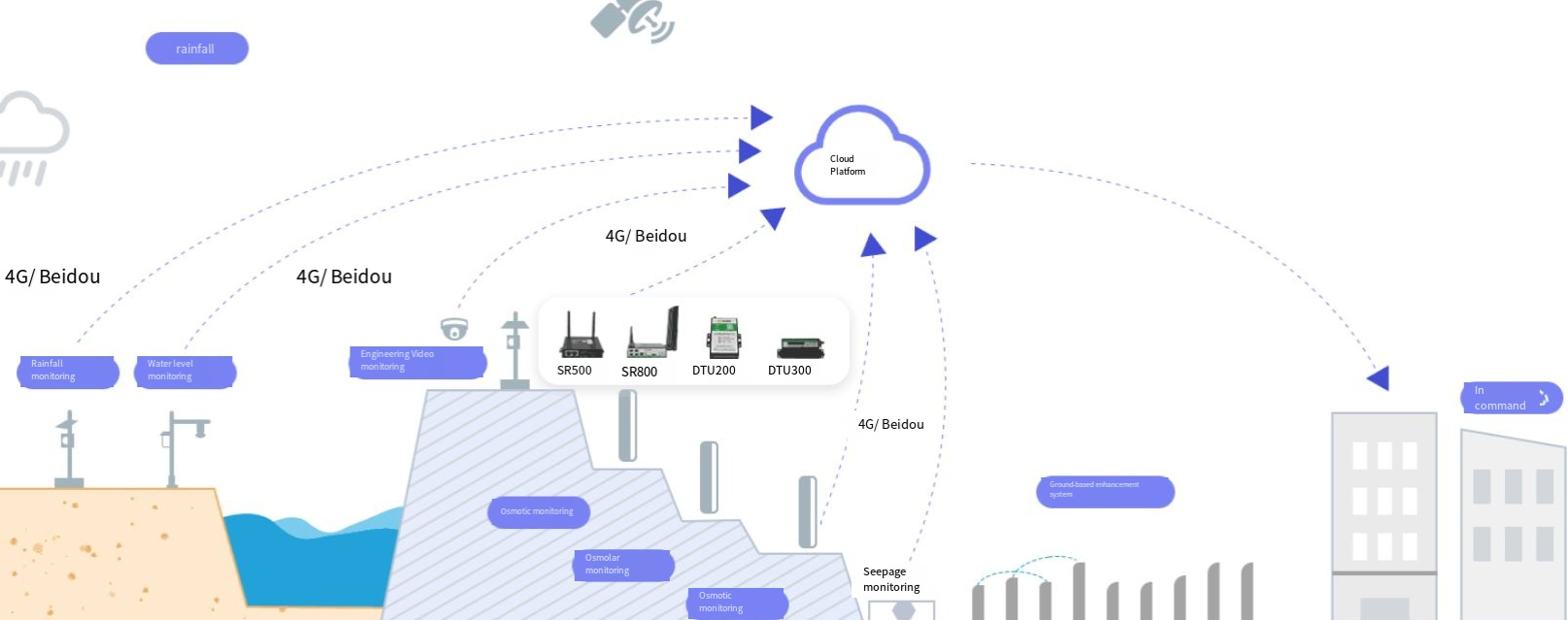

The complex environment in metallurgical plants makes deploying wired networks difficult and costly; steel structures and high dust environments lead to severe wireless signal attenuation, and there are many strong electromagnetic interference scenarios, making network coverage difficult. These pain points have all become bottlenecks for enterprises to achieve automation. For example, remote control of gantry cranes requires a considerable amount of uplink bandwidth, which traditional wireless networks do not provide.

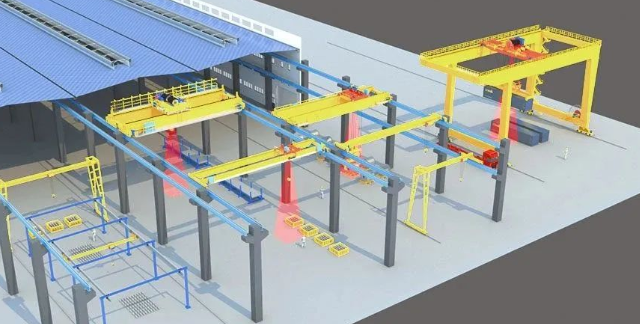

Factory Gantry Crane Remote Monitoring Application Introduction

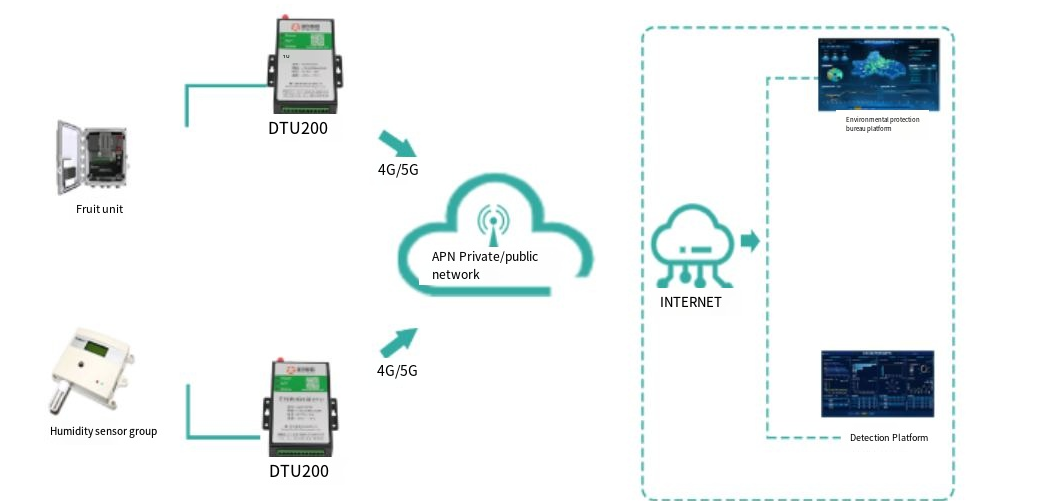

Data Collection

Mainly includes tilt angle sensors, photoelectric encoders, electrical control systems, stroke sensors, human-machine interfaces, video systems, etc.

Network Communication

The monitoring system (sensor data, monitoring data, control data) uses 5G networks to establish long connections with the production business monitoring system to achieve remote transmission and control of monitoring data and status data. An operator's dedicated 5G network is used to ensure data does not leave the plant.

**Monitoring System**

Video monitoring system: Mainly views peripheral video information of the gantry crane to assist remote operation and safety monitoring. The production business system mainly implements status monitoring and business operations according to needs, enabling remote control and monitoring.

KEY-IOT

KEY-IOT