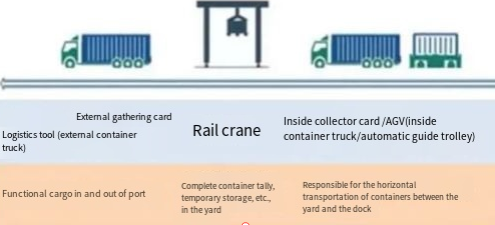

As a hub for transportation, ports play a pivotal role in promoting international trade and regional development. About 90% of global trade is carried by the shipping industry, so operational efficiency is crucial for ports. In the era of "Industry 4.0" and "Internet of Things+", ports are also undergoing digital and fully automated transformations. With the arrival of the global 5G technology wave, Startdtu is helping IoT+5G together to continuously upgrade ports with automation and intelligence, using 5G to promote port informatization and automation, and build "safe, eco-friendly, efficient" smart ports.

SR810 Smart Port Solutions:

01Remote operation solutions for gantry cranes

Cameras and PLCs are installed on the gantry cranes. Operators in the control room perform remote control based on video monitoring, completing precise positioning, lifting containers, etc. of the gantry cranes through 5G network slicing, achieving remote operation, reducing labor costs, and improving operational safety.

Vehicle-road coordination: Communication between carts, and between carts and port roads enables precise positioning of carts and real-time awareness of surroundings.

Remote control: Startdtu's SR810 industrial grade 5G CPE, combined with low latency cameras, enables remote control of port gantry cranes and shore bridges.

5G network slicing: Logically partitioning a physical network into multiple virtual end-to-end networks, each with logically independent network resources, and isolated from each other. Therefore, errors or failures in one slice do not affect other slices. 5G slicing creates multiple virtual 5G networks to support more services. It meets the two key needs of the 5G remote control application for tire-type gantry cranes: low latency for PLC heartbeat packets and high uplink bandwidth for video, enabling real-time transmission and remote control of 16 HD video channels of the gantry crane.

5G network slicing enables creating multiple virtual networks on top of a shared physical infrastructure to deliver optimized services for different applications. Key benefits:

- Isolation - Each slice operates independently, enhancing reliability. If one slice fails, others are not impacted.

- Customization - Each slice can be tailored for specific requirements like high bandwidth, low latency, security levels, etc.

- Efficiency - Network resources are utilized more efficiently by allocating to applications only what they need.

- Flexibility - Easy to add, remove or modify slices on-demand to meet changing needs.

- Differentiation - Ability to offer customized solutions and service levels for different applications or customers.

So for applications like remote control of gantry cranes, network slicing provides the isolation, low latency, and high bandwidth needed for video feeds and control data. This enables new industrial use cases leveraging 5G capabilities.

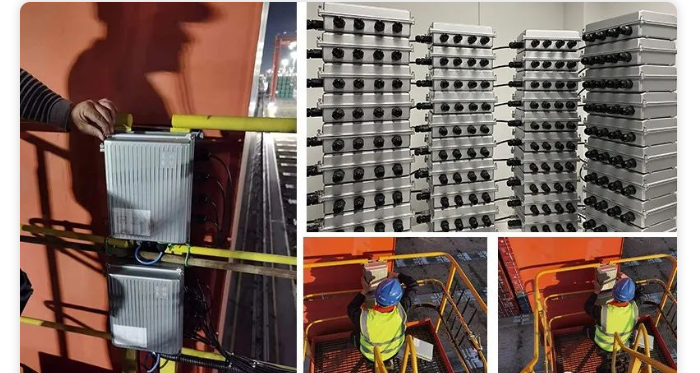

Gantry crane product on-site installation diagram

02Remote control solutions for bridge cranes

In the loading and unloading area, bridge cranes are the main business units. Their communication needs are divided into remote control and monitoring. The remote control scenario requires the uplink bandwidth generated by the number of cameras on a single bridge crane simultaneously transmitting to be multiples of that for a gantry crane. At the same time, bridge cranes are deployed relatively densely, with multiple bridge cranes typically deployed along a 1 km long port line.

Container ports typically use alongside berthing. In addition to sufficient water depth and shoreline length, cable bollards and fenders are also installed at berths. In addition to meeting the production and monitoring needs of bridge cranes and TOS terminals, the SR810 Industrial CPE also needs to provide 5G network coverage for docked ships.

SR810 Industrial 5G CPE has six main features:

Network equipment sharing is maximized, spectrum is flexibly shared or completely isolated, and the dedicated network version/function updates are completely synchronized with the public network.

It can identify public and private network users and enable network slicing.

Network on demand - resources can be configured as needed.

Through local gateways, shortest routing and lowest latency can be achieved.

Convenient operator dedicated network service delivery in this architecture.

Enterprises and operators achieve win-win results. Enterprises purchase services to obtain dedicated network capabilities and light asset deployment of digital infrastructure. Operators unleash spectrum and network potential, with monetization of network capabilities delivering incremental revenue.

Others Product Features

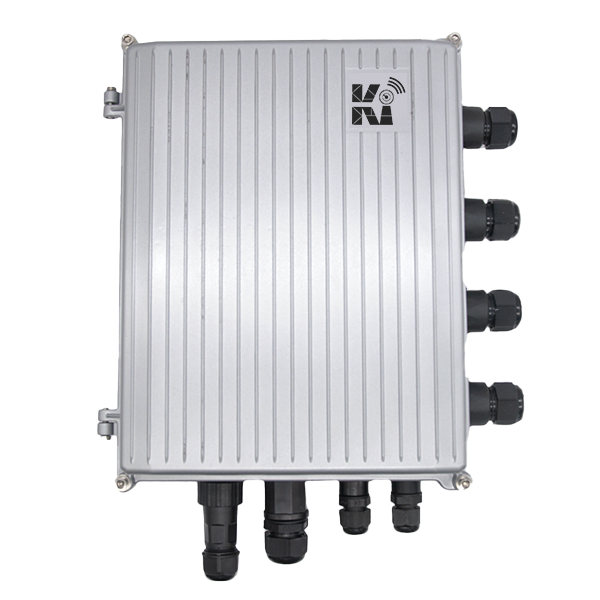

Our self-developed 5G industrial grade CPE is an IP66 high protection grade 5G CPE communication device with a metal waterproof casing, suitable for various industrial environments indoor and outdoor. Relying on 4G/5G wireless WAN redundancy and Wi-Fi wireless LAN and other technologies, it provides uninterrupted multi-network access capabilities. With comprehensive security and wireless services, it provides users with high-speed and stable data transmission channels.

KEY-IOT

KEY-IOT