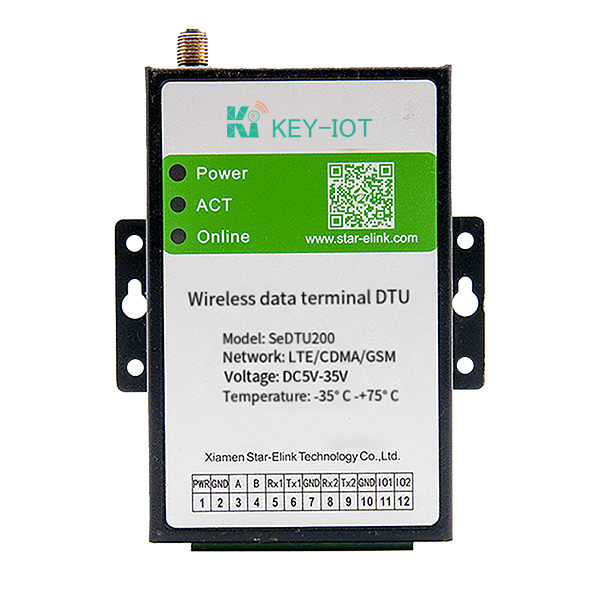

As an intelligent industrial IoT gateway device, Startdtu DTU200 has been widely used in industrial fields to enable device interconnection and real-time data transmission. Here, we will introduce a project case of Startdtu DTU200 in industrial control systems.

I. Project Background

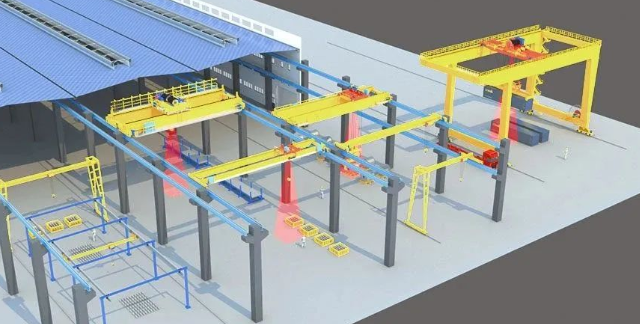

This project involves a large steel enterprise that aims to achieve industrial monitoring and data intelligence through digital technologies, improving production efficiency and management. However, in actual application, there was a lack of effective interconnection between the enterprise's equipment and systems, with unstable data collection and transmission, resulting in production data unable to be aggregated and analyzed in a timely manner, and unable to effectively guide production scheduling and decision-making.

II. Project Solution

To solve the enterprise's industrial monitoring and data transmission problems, the enterprise chose Startdtu DTU200 as the IoT gateway device. DTU200 has high reliability, flexibility and compatibility, supports multiple communication interfaces and protocols, and can be customized and integrated into systems according to user needs

. Based on the actual situation of the enterprise, Startdtu provided a complete solution, including:

Device Access

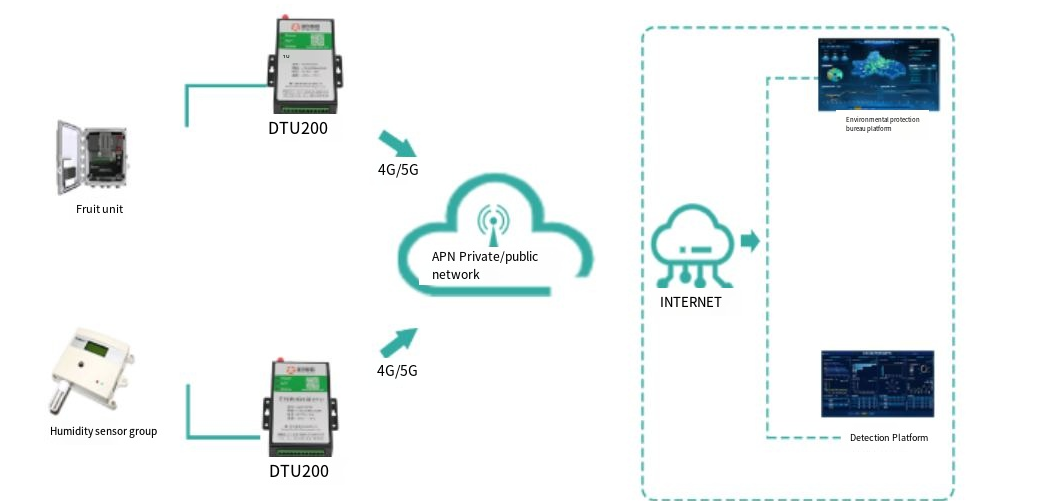

DTU200 supports multiple communication interfaces and can interconnect with different types of devices. In this project, DTU200 connects to multiple temperature, humidity and oxygen sensors via the RS485 interface to collect real-time equipment data and upload it to the cloud platform.

Data Transmission

DTU200 supports multiple communication protocols and can transmit data to different types of systems. In this project, DTU200 transmits equipment data to the cloud platform via the MQTT protocol. MQTT has characteristics such as lightweight, high efficiency, and reliability, enabling real-time transmission and remote control of device data.

Data Storage

DTU200 can store device data locally or on a cloud platform. In this project, DTU200 uploads device data to the cloud platform and stores it in the database. The enterprise can view device data and conduct data analysis and processing through the cloud platform.

Data Analysis

DTU200 provides a complete data analysis and processing solution. The enterprise can view real-time device data through the cloud platform, and conduct data analysis and processing. Through data analysis, the enterprise can understand the operating status and health of devices, timely discover equipment failures and problems, and perform maintenance and repairs.

Remote Control

DTU200 can achieve remote control and management of devices through the cloud platform. In this project, the enterprise can remotely control and manage devices through the cloud platform, such as setting the operating mode and parameters of devices, troubleshooting and repairing device failures, etc. Through remote control, the enterprise can quickly respond to production needs, adjust the operating status and parameters of devices, and improve production efficiency and quality.

III. Application Effect

Through the application of Startdtu DTU200, the enterprise achieved device interconnection, real-time data transmission, and improved industrial monitoring and data intelligence. The specific application effects are as follows:

Real-time Monitoring

Through the device data uploaded by DTU200, the enterprise can monitor the operating status and health of devices in real time, timely discover equipment failures and problems, reduce downtime and production losses.

Data Analysis

Through the device data uploaded by DTU200, the enterprise can conduct data analysis and processing, understand the operating status and health of devices, optimize production scheduling and decision making, and improve production efficiency and quality.

Remote Control

Through the device data uploaded by DTU200, the enterprise can remotely control and manage devices through the cloud platform, quickly respond to production needs, adjust device operating status and parameters, and improve production efficiency and quality.

IV. Summary

As an intelligent industrial IoT gateway device, Startdtu DTU200 has been widely used in industrial fields to achieve device interconnection and real-time data transmission. Through this project case, we can see that DTU200 has features such as high reliability, flexibility and compatibility. It can be customized and integrated into systems according to user needs to achieve industrial monitoring and data intelligence. We believe DTU200 will continue to play an important role in the future development of industry, helping enterprises realize digital transformation and intelligent upgrading.

KEY-IOT

KEY-IOT